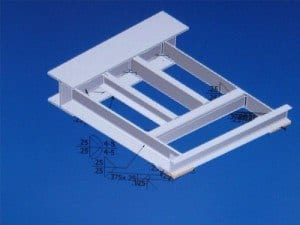

Design and engineering support for sheet metal components are part of our complete line of fabrication services. You can provide us with hard copies or CAD drawings, which we will use as a framework to build your components. CAD drawings in formats, such as AutoCAD, eDrawings, Solidworks, Adobe PDF (Acrobat) and DXF are accepted. We are always adding new capabilities and if you use a format that is not listed, just ask us about it.

Equipped with up-to-date, effective design methodology, we can address your unique needs for prototype or sample parts as well. All practical challenges likely to rise during the production are considered during the design stage. Our experienced staff work with our customers to precisely understand the application requirements to get the job done right and on time.